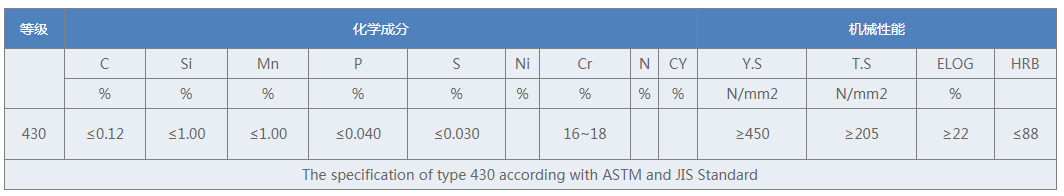

400系不銹鋼常用于建筑裝飾用、燃 油燒嘴部件、家庭用器具、家電部件 等,日常用的家用電器大都是用430 不銹鋼制作的。

| 等級 | 化學成分 | 機械性能 | |||||||||||

| C | Si | Mn | P | S | Ni | Cr | N | CY | Y.S | T.S | ELOG | HRB | |

| % | % | % | % | % | % | % | % | % | N/mm2 | N/mm2 | % | ||

| 430 | ≤0.12 | ≤1.00 | ≤1.00 | ≤0.040 | ≤0.030 |

|

16~18 |

|

|

≥450 | ≥205 | ≥22 | ≤88 |

| The specification of type 430 according with ASTM and JIS Standard | |||||||||||||

厚度公差

|

鋼帶厚度允許偏差(GB/T3280-2007) |

||||

|

公稱厚度 |

厚度允許偏差 單位:mm |

|||

|

寬度<125 |

125≤寬度<250 |

250≤寬度<600 |

600≤寬度<780 |

|

|

≥0.05~<0.10 |

±0.006 |

±0.001 |

±0.001 |

- |

|

≥0.01~<0.20 |

±0.008 |

±0.012 |

±0.015 |

±0.015 |

|

≥0.20~<0.30 |

±0.012 |

±0.015 |

±0.015 |

±0.020 |

|

≥0.30~<0.40 |

±0.015 |

±0.020 |

±0.020 |

±0.025 |

|

≥0.40~<0.60 |

±0.020 |

±0.025 |

±0.030 |

±0.025 |

|

≥0.60~<1.00 |

±0.025 |

±0.030 |

±0.035 |

±0.035 |

|

備注:t為公稱厚度 |

||||

|

分條公差 單位:mm |

||||||||

|

寬度/厚度 |

<0.59 |

0.6~0.8 |

0.8~1.0 |

1.0~1.25 |

1.25~1.6 |

1.6~2.0 |

2.0~2.5 |

2.5~3.15 |

|

<250 |

±0.04 |

±0.045 |

±0.05 |

±0.05 |

±0.06 |

±0.07 |

±0.08 |

±0.09 |

|

251~400 |

±0.04 |

±0.045 |

±0.05 |

±0.05 |

±0.06 |

±0.08 |

±0.08 |

±0.09 |

|

401~630 |

±0.04 |

±0.045 |

±0.05 |

±0.06 |

±0.06 |

±0.08 |

±0.09 |

±0.10 |

|

631~1000 |

±0.04 |

±0.05 |

±0.05 |

±0.06 |

±0.07 |

±0.09 |

±0.10 |

±0.11 |

|

1001~1250 |

±0.05 |

±0.05 |

±0.06 |

±0.07 |

±0.08 |

±0.10 |

±0.11 |

±0.12 |

|

1251~1524 |

±0.08 |

±0.09 |

±0.10 |

±0.12 |

±0.15 |

±0.17 |

±0.2 |

±0.25 |

切片公差

|

切片公差 |

||

|

長度 |

長度公差 |

對角線公差 |

|

400~999 |

±0.3 |

≤0.5 |

|

1000~2438 |

±0.5 |

≤1.0 |

|

2349~3658 |

±0.8 |

≤1.0 |

|

3659~6000 |

±1.0 |

≤2.0 |

|

表面粗糙度加工等級 |

||

|

表面加工代號 |

表面粗糙度Ra |

加工方法 |

|

BA |

|

鋼帶冷軋后經過光亮熱處理的表面 |

|

TR |

|

鋼帶冷軋后經過清洗的表面 |

|

HL |

|

用適當研磨粒度研磨出連續線條的軋輥軋制使鋼帶表面呈一定的縱向磨紋 |

|

S |

|

適用砂粒加工的軋輥軋制的鋼帶表面 |

|

80# |

0.8~1.0 |

用80#粒度研磨的軋輥軋制的表面 |

|

100# |

0.6~0.8 |

用100#粒度研磨的軋輥軋制的表面 |

|

150# |

0.4~0.6 |

用150#粒度研磨的軋輥軋制的表面 |

|

180# |

0.3~0.4 |

用180#粒度研磨的軋輥軋制的表面 |

|

220# |

0.15~0.3 |

用220#粒度研磨的軋輥軋制的表面 |

|

320# |

0.08~0.15 |

用320#粒度研磨的軋輥軋制的表面 |